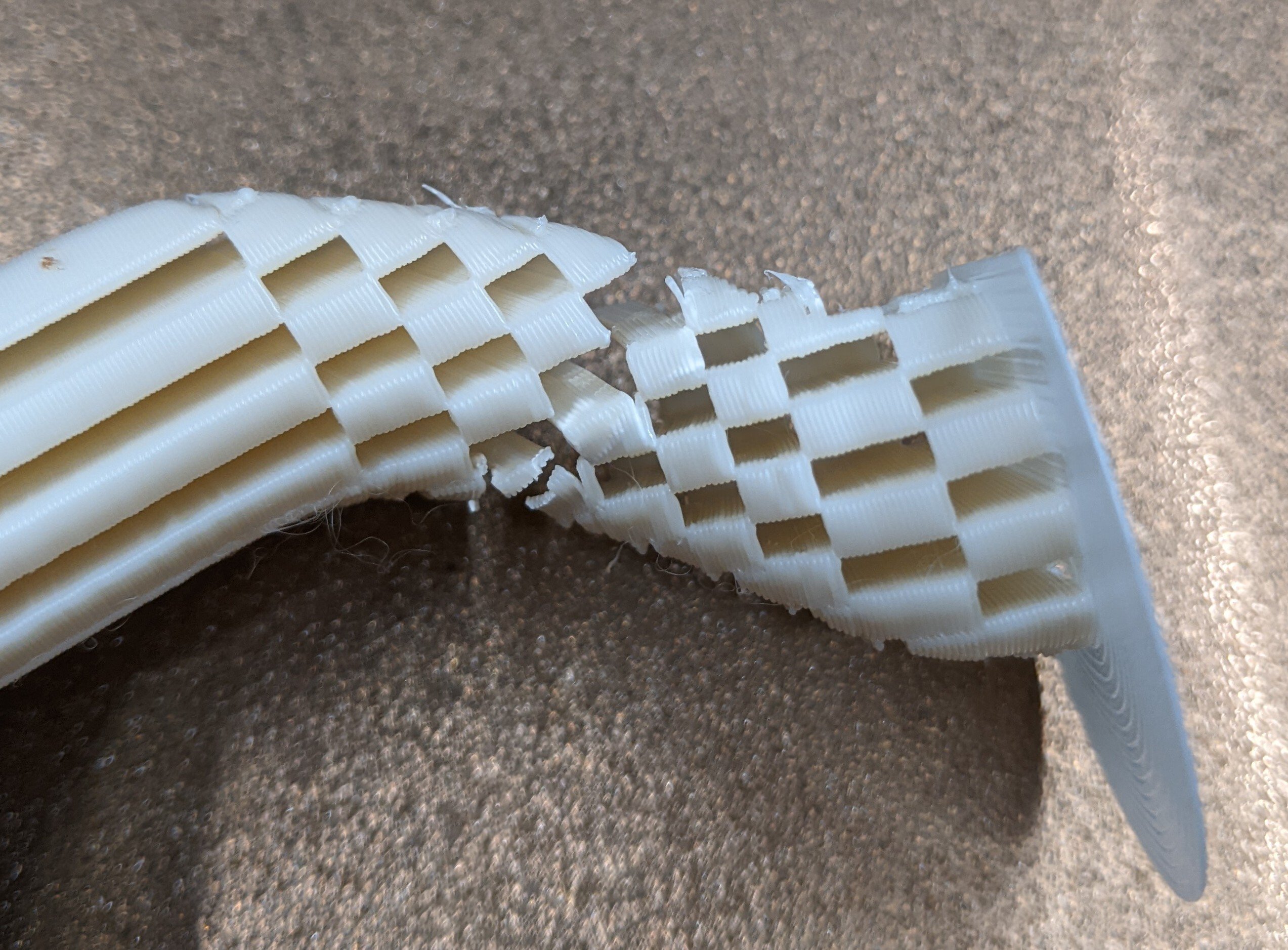

At least so far. The first go round had the nozzle crash into the tree support, resulting in a layer shift. The good news is that the print stayed very firmly stuck to the bed.

I’ve reset, lowered my extrusion multiplier a smidge, switched to a more traditional support pattern, and am going for it again. Wish me luck!

It’s called the ADHD mod

What the holy hell is this nonsense?

You guys will do anything to keep from buying a good printer won’t you?

I’ve done 21 hours prints in my damp cold basement without issue.

You guys make me feel so competent haha.

Imagine feeling so confident to indirectly call Voron a bad printer and tell people how to spend money.

Go get yoursel something to work on instead of mocking other for their temporary solutions.

ASA and ABS are warp prone and this is an 11" / ~275mm wide print that’s equally tall 🤷

The build volume of my printer means lots of surface area for the acrylic enclosure, which in turn makes it hard for me to exceed a 50°C chamber temp, despite 4x bed fans.

The next print, with normal supports, pulled the bed off the magnetic build plate. Insulation eliminated warping and let me pull off the print.

I do agree that a “nicer” enclosure is the preferred method. I have zero issues with PETG at this size. I’ve never tried PLA on this printer, but it should be fine too.